Key Highlights

Category

Manufacturing/Transportation

Location

Headquarters: Lisle, Illinois, USA

Solution highlights

- Modern Data Platform: Cloudera Enterprise

- Cloudera SDX: Shared catalog, security, and governance

- Workloads: Data Warehouse, Data Science & Engineering

- Components: Apache Spark™, Apache Impala, Apache Kafka®

- BI & Analytics Tools: Information Builders WebFOCUS In-Document Analytics, Microsoft Power BI, Microsoft SQL Server Analytic Services Models, Microsoft SQL Server Reporting Services, SAS Enterprise Guide, Tableau Desktop, Tableau Server

- Data Science Tools: Python, R, Scala

- ETL Tool: IBM InfoSphere DataStage

Applications supported

- IoT

- Predictive maintenance

- Remote diagnostics

- Route optimization

Data sources

- Vehicle sensors

- Navistar and third party systems for meteorological, geolocation, vehicle usage, traffic, historical warranty, and parts inventory information

Impact

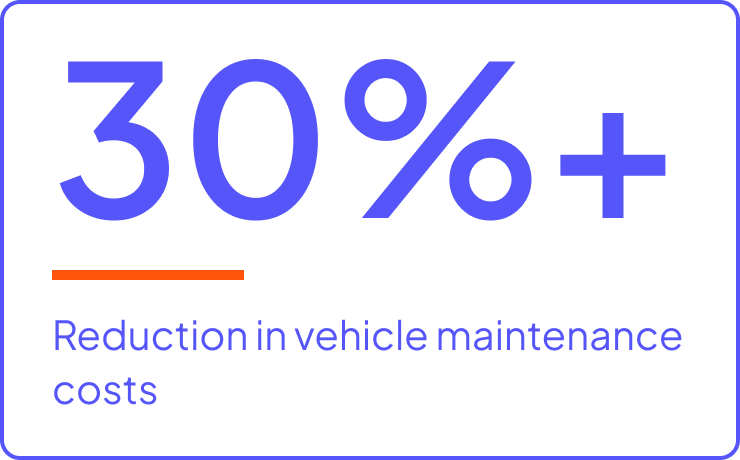

- Reduced maintenance costs and vehicle downtime by more than 30 percent

- Decreased the maintenance cost-per-mile for one company’s vehicles to less than three cents, down from 12 to 15 cents

- Reduced the number of tows one school district needed year over year

- Enables Navistar to analyze billions of rows of data in hours instead of weeks

Navistar delivers IoT-enabled predictive maintenance, vehicle diagnostics and management, and route optimization to help fleet and truck owners minimize vehicle downtime.

Navistar is a leading manufacturer of commercial trucks, buses, defense vehicles, and engines, widely known for its International® Truck and IC Bus® brands.

Challenge

“Truck drivers get paid, freight haulers get paid if the truck's moving,” said Terry Kline, chief information officer, Navistar. “So if that truck's not moving, nobody's making money and someone's not getting the package they expect. As a result, our focus is on uptime, and our goal is zero downtime related to unplanned maintenance.”

Typically, vehicle manufacturers schedule vehicle maintenance based on miles traveled or time since last appointment. But these are very rudimentary and only two of thousands of data points that can signal the need for maintenance. Unscheduled maintenance and vehicle breakdowns account for a large share of total costs for vehicle owners.

To help fleet and vehicle owners move from a reactive approach to a more predictive model, Navistar needed to analyze a wider range of data in real time, including vehicle sensor data. However, its traditional data warehouses couldn’t support the growing volume of fast-moving, high-volume telematics data. “As we collected more data, the analytic process slowed to a near halt on our legacy systems,” said Ashish Bayas, chief technology officer, Navistar.

Solution

Navistar built an IoT-enabled remote diagnostics platform, called OnCommand® Connection, on Cloudera Enterprise with SDX. The platform brings in over 70 telematics and sensor data feeds from more than 375,000 connected vehicles—including engine performance, truck speed, acceleration, coolant temperature, and brake wear. This data is then correlated with other Navistar and third party data sources, including meteorological, geolocation, vehicle usage, traffic, historical warranty, and parts inventory information. The platform currently stores over 60 terabytes (TB) of data and uses machine learning and advanced analytics to automatically detect engine problems early and predict maintenance requirements.

Fleet and vehicle owners can now monitor truck health and performance from smartphones or tablets, prioritize needed repairs, and quickly identify the nearest dealer service locations that have the relevant parts in stock, available technicians, and available service bays.

Implementation

Navistar first built a prototype in September 2014. The company put the platform into production just six months later, and today is expanding its analytic services. “We continue to innovate using the Cloudera platform to gain valuable insights from growing sources of information and offer new applications against the data for different users,” said Kline.

With Cloudera SDX, Navistar has unified controls for its data catalog, security and governance across its many analytic workloads. As a result, IT staff can set policies once across all its analytic workloads, making it faster to deploy new applications, easier to maintain compliance with its data agreements, and more secure.

“We have a number of different applications running after our data every day, and Cloudera SDX is key to making that happen at Navistar,” said Kline. “SDX is foundational in how we track, govern, and protect our data.”

Results

With OnCommand Connection, Navistar has helped fleet and vehicle owners reduce maintenance costs by more than 30 percent. One Navistar customer reduced the maintenance cost-per-mile for its vehicles, which previously was 12 to 15 cents, to less than three cents.

Early detection also minimizes downtime and towing costs. In addition, when downtime occurs, vehicle owners typically lose up to US$1,000 in revenue per vehicle daily. With over 375,000 vehicles across 2,300 customers, the total impact can be significant.

Navistar also uses the platform to help school buses run safely and on time. One school district with 110 buses that travel 1.5 million miles annually reduced the number of tows needed year over year, thanks to the predictive insights.

“The results are overwhelmingly positive,” said Troy Clarke, CEO, Navistar. “Using real-time big data to frame business decisions and deploy proactive maintenance has opened new revenue streams and delivered additional customer value.”